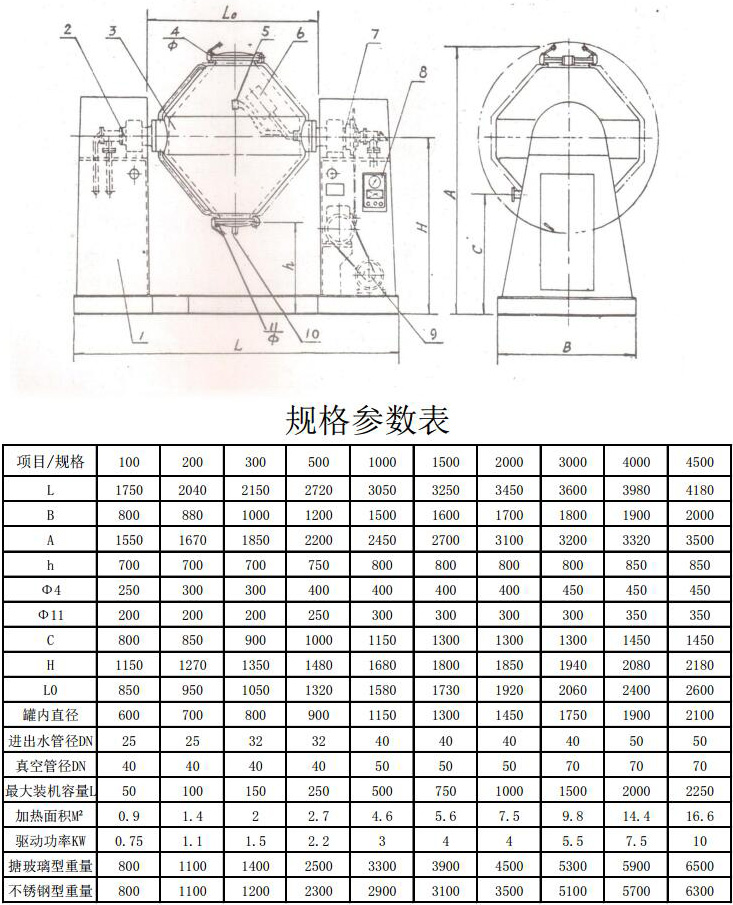

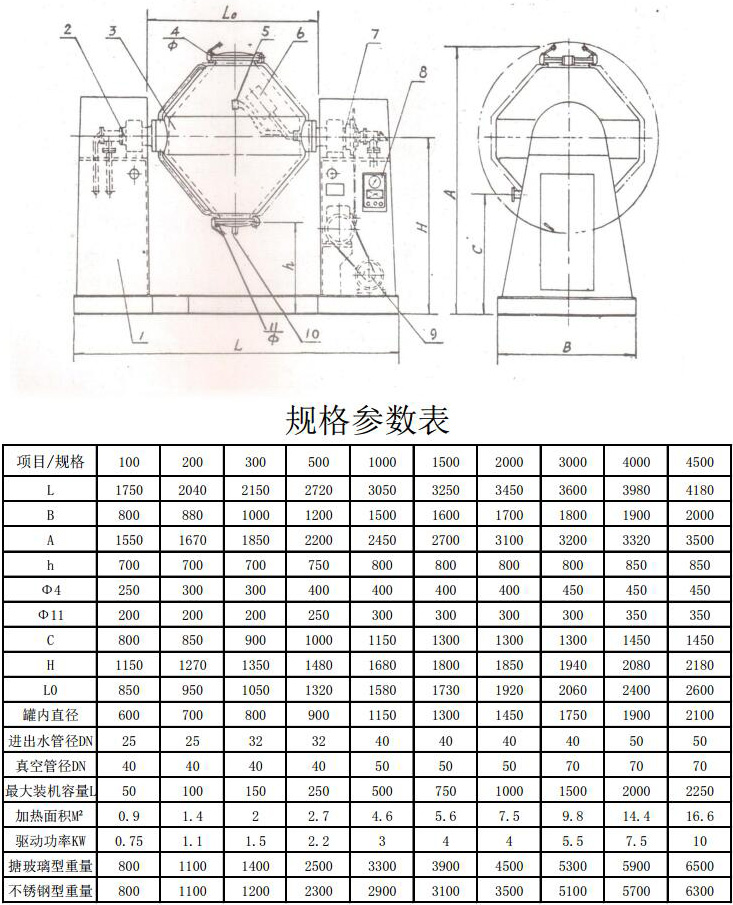

Dryer

Product Name: Dryer

Manufacturer: Shen Yue Purification

When the hydrothermal fluid (usually hot water 80-100 C, heat conducting oil 80-150 C) is introduced into the machine, heat is transferred through jacket to the tank wall to indirectly heat the wet material. The moisture of the wet material is heated and vaporized, and the vaporized water is pumped out from the vacuum pumping system in time. In addition, the tank body rotates slowly and the contact surface between the wet material and the tank wall is constantly updated, which makes the drying process continue to be uniform. That's ok.

When the wet material is heated in vacuum, the surface vapor pressure of the wet material is much higher than the vapor partial pressure of the evaporation space, so the vaporization rate of the moisture is higher than that of the wet material at atmospheric pressure. At the same time, at higher vacuum, the vaporization point of water decreases (related to vacuum), so it is necessary to use a lower temperature heat source for drying and heating.

Our new HZG system, stainless steel, glass-lined double cone rotary vacuum dryer, is currently more advanced in the field of domestic drying equipment. The new scientific model has the advantages of energy saving, high drying heat efficiency (80-185 C), uniform and sufficient drying, and no pollution of materials. It is very suitable for drying various powder granular materials. At the same time, the machine can add additives synchronously in the drying process of materials and complete mixing and spraying in the same equipment. Granulation, drying and other diversified unit operation. The solvent can be recovered by external condensation device while drying. It is a highly intensive multi-functional drying equipment.

Pharmaceutical industry: drying, mixing and solvent recovery of intermediates, granular products, fine granules, powders.

Food industry: raw materials, food raw materials, dried fruit food drying and raw material mixing.

Feed industry: drying, mixing and solvent recovery of feed, biological protease, additives, etc.

Chemical industry: drying, mixing and solvent recovery of powder particle intermediates, finished products, such as organic, inorganic chemicals, pesticides, dyes, etc.

Metallurgical industry: drying, mixing and solvent recovery of metal-like oxide, compound particle powder and cemented carbide powder.

Plastics industry: resin raw materials, plastic particles, additives and other drying.

Fine ceramics industry: drying, mixing and solvent recovery of carbides, carbides and halides.

The wet material is added to the closed rotating tank and dried in vacuum and low temperature, which is a major feature of the machine. Therefore, it is especially suitable for materials with the following requirements:

1. Can't accept high temperature and easy oxidation; (e.g. heat-sensitive and oxygen-repellent materials)

2. Require the material not to be polluted during drying: (the tank is sealed to exclude dust and impurities from outside)

3. Volatile substances excluded during drying should be recovered; (e.g. the recovery of some valuable solvents)

4. Require the finished product to be dried evenly or with low moisture content; (After drying, the moisture content can be less than 0.5%)

5. There are strict restrictions on the content of metal ions in the drying process; (glass-enameled glaze is applied on the wall of the tank of glass-enameled dryer, and the contact between material and metal wall is eliminated)

6. Mixing material in drying process; (The double cone tank has excellent mixing effect on material in rotary motion)

7. Easy to operate; Vacuum rotary dryer is easy to operate, with fewer staff and low labor intensity. Because the material has no escape, the environmental hygiene has been improved. (Suitable for dust-free workshop with high requirements)

8. Because the inner structure of the tank is simple and the spraying device which can adjust the flow rate is installed, it has the function of self-cleaning; (It is suitable for drying many kinds of materials in turn without cross-infiltration of impurities)

There are a group of senior engineers and professionals who engaged in designing, R&D, production, manufacturing, sales and services of various types of industrial gas equipment for long period of time in the Company!

How to contact Shen Yue Purification?

Mob:156-0613-1715 Tel:0512-65892711 Fax:0512-65892711 QQ:123456789 E-mail:suzhoushengyu@163.com Add:52, Qinfeng Road, Suzhou National new and hi-tech industrial Development zone, Jiangsu | |

Keywords:Suzhou Shenyue Purification website,Ammonia decomposition hydrogen production equipment

![]() R & D

R & D![]() production

production![]() customization

customization